Vespol FIX

VENTILATED ELEVATION WITH INVISIBLE FIXING OF FACING BOARDS VESPOL FIX

The main parts of the solution VESPOL FIX is as follows:

1. Supportive framework of facing.

2. Thermal insulation.

3. The facing itself.

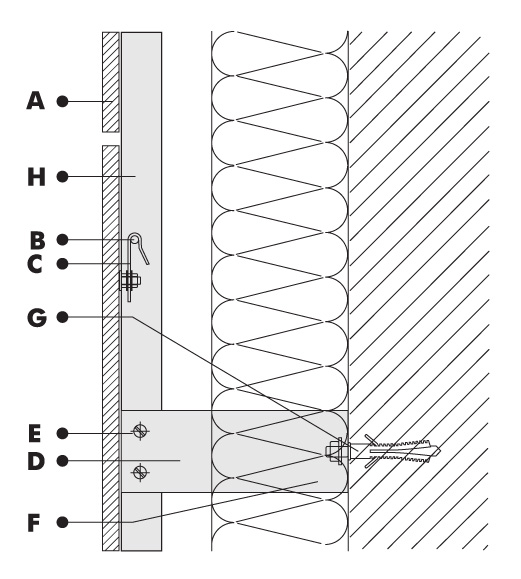

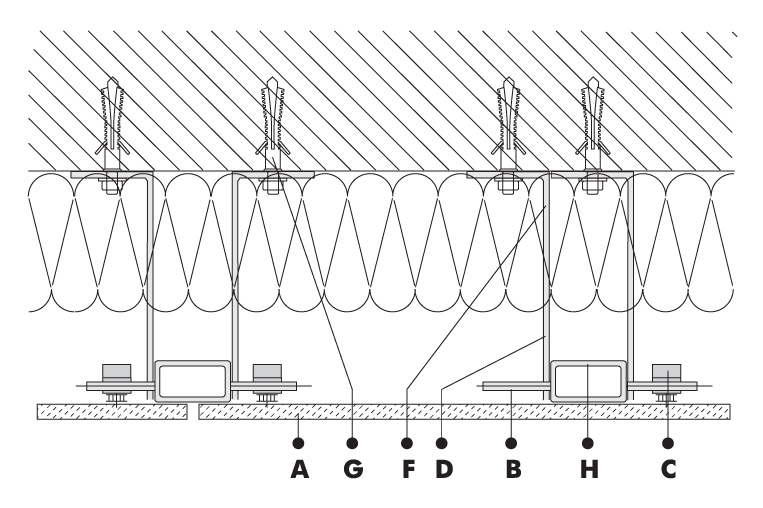

1. The supportive framework is made of closed aluminium profiles with dimensions 40/20, 50/30, 60/20 mm (H) and stain-less steel bolts with length of 150 mm and 6 mm diameter (B) for hanging the facing. Distribution of bolts and framework profiles depends on facing dimensions. Elements of the framework are fixed to the base (wall) by aluminium anchors (F).The anchors dimensions (F) are settled by the designer

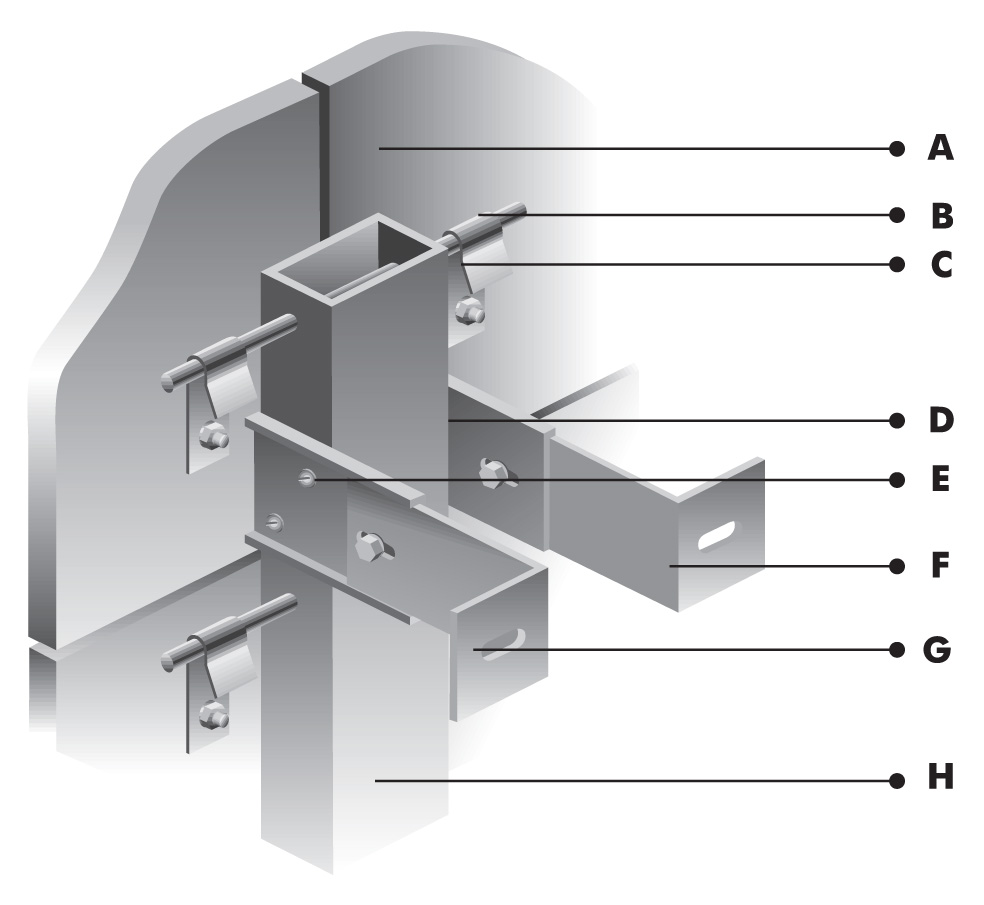

The system of invisible fixing of elevation boards

VESPOL FIX (axionometry)

Ad. 2. Thermal insulation

Kind, density and thickness of thermal insulation results from thermal-technical calculations. Hydrophobic, hard mineral wool is used as thermal insulation. Insulation boards are fixed to the walls by means of head connectors of plastics. It is possible to cover the insulation by steam-permeable foil.

Ad. 3. The facing

A kind of elevation facing – natural stone (granite, marble), artificial stone – gres, laminate.

Natural stone: dimensions of facing boards are settled by the architect and the designer of company VESPOL INVEST for each concrete building. In this technology thickness of used stone is 2 cm at any height of the building (there are differences in quantity and kind of used connectors). It reduces elevation weight of 30 to 50% in comparison with traditional fixing.

Artificial stone – gres: boards dimensions 40/40, 30/60,

40/60, 60/60, 80/80, 50/100, 60/120, 100/100, 120/180 cm.

Before fixing the elevation facing, ceramic and stone, the rear surface of boards is glued with net of glass fibre. It secures against falling of the facing being mechanically damaged on elevation.

- Elevation board (A)

- Bar (B)

- Connector of elevation board(C)

- Rectification extension (D)

- Self-screwing pin (E)

- Basic anchor (F)

- Stretcher (G)

- Bearing profile (H)